Flow Chart For Mayonnaise Production

In industrial production of mayonnaise it is important to both get a product of high quality and to avoid phase inversion. The high volume of the internal phase gives these emulsions their great structural viscosity.

Mayonnaise Margarine Ppt Video Online Download

And batch production of mayonnaise and ketchup.

Flow chart for mayonnaise production

. Mayonnaise is a popular condiment that consists of oil water and egg yolk or substitute. Spices essential oils 05. For example vegetable oil sunflower soya olive corn peanut and others serving as one of the main components must pass through a refining process.Ingredients Mayonnaise Salad mayonnaise Salad mayonnaise Salad cream Oil 80 67 50 35 Egg yolk liquid 6 - - - Sugar 26 26 26 26 Salt 13 13 13 13 Vinegar 10 35 35 35 35. Under German delicatessen industry guidelines mayonnaise used as salad dressing must have an oil. GEAs one-pot BATCH FORMULA Mixer is ideally suited to processing mayonnaise and other challenging products.

To investigate how the quality and phase inversion point are affected by changes in the production a high shear mixer and an immersion blender were used to make mayonnaise. The ingredients used in mayonnaise can be divided into several phases eg. For mayonnaise processing it is important to have a reduced oil droplet size and to avoid trapping micro bubbles in the product.

Disclosed is a mayonnaise base which is mixed. Also as flowchart shows every step of a process in clear and explicit detail employees can know their duties explicitly. Gums and thickeners such as starches are used in low fat products to replace the viscosity and bulking effect of the oil to enhance mouthfeel and to ensure that a stable emulsion is formed.

A mayonnaise production line consists of several compulsory sets. Lemon juice 05. The stirring speed temperature egg content egg type and oil content were changed to see how the.

The emulsion is prepared by adding the surfactant to the water and mixing this solution with an equal volume of oil to form a crude emulsion. Below is a simple flowchart example showing the beer production process. The SPP includes all components necessary for the preparation of mayonnaise ketchup and sauces.

But mechanical agitating can make it evenly dispersed to form the emulsion. Mayonnaise Process Flow Chart Template ism 9 news for february 2015 consumeraffairs health yahoo lifestyle colloid wikipedia timeline of united states inventions 18901945 wikipedia www lextutor ca dennis miller rants and quotes igor n english vocabulary word list alan beale s core strontium side effects are overblown get the facts stepping stones to caring for our children 3rd edition. For RD pilot scale and small scale production.

In mayonnaise production egg yolk is used as an emulsifier at a level commonly between 4 and 8. If you have any complain about this image make sure to contact us from the contact page and bring your proof about your copyright image. The remainder of the steps are the same as the cold preparation process.

All trademarks referenced here in are. No Process Required Qty Required Capacity 1 Liquid Egg Storage Tank with agitator 1 600 Kg 2 Water Storage tank with agitator 1 550 Kg 3 Oil Storage Tank with agitator 1 4500 Kg 4 Vinegar Storage Tank with agitator 1 350 Kg 5 Homogenizer 1 700 750 KgHr 6 Filler 1 1350 Jarshr. After placing it for a while oil and water will be separated.

Relabel Production log Daily review by production supervisor 5 Refrigerate Pathogen growth Store at 45F or less Cooler temp. 8252017 31024 pm. This process is often semi-automated and usually under vacuum.

SPX Flow Technology supplies GS emulsifying systems under the names ERS which is a continuous system and EBS which is a batch system. Download Free Workflow Templates Smartsheet. Mixing is a key process that affects the consistency and quality of mayonnaise.

An oil phase only. Mayonnaise is an oil-in-water emulsion which can contain up to 80 oil. To obtain a high-quality product the raw materials have to meet certain requirements.

Water makes up the continuous phase of the formula at 5-15 with various other additives for flavor such as salt. Only the EBS will be described in this application sheet. Some countries however use the semi-hot process.

The manufacturing of mayonnaise is to mainly take advantage of adipose emulsification results. Large scale production is normally carried out using a specifically designed plant. For example with flowcharts they can easily recognize which part of the process leads to a poor efficency so that they can make a decision to improve accordingly.

Production Mayonnaise is a water-oil emulsion with eggs. Mayonnaise-type emulsions are best prepared with a hydrophilic surfactant. Product buffer continuous process for mayonnaise production.

In Europe mayonnaise must have a total fat content of at least 70 and an egg yolk content of at least 5. The BATCH FORMULA Mixer. Before starting the first batch the entire system should be checked to make certain that all pipe joints are tight because air suction can be very harmful by breaking the emulsion.

A typical recipe is as follows. Mayonnaise is an oil-in-water emulsion. Different countries have various recipe requirements for the production of products such as mayonnaise.

Oil and water itself is incompatible. A section of components resting tanks for steam treatment the main mixer tank and a homogenizer or colloid mill. Here the water phase water salt sugar mustard powder is heated to 92 C and then cooled back down to 30 C.

Flowcharts help production managers better plan and coordinate the production process. Mayonnaise and other emulsi ed sauces are generally prepared cold. Mayonnaise is an oil-in-water emulsion typically containing more than 74 vegetable oil minimum 65.

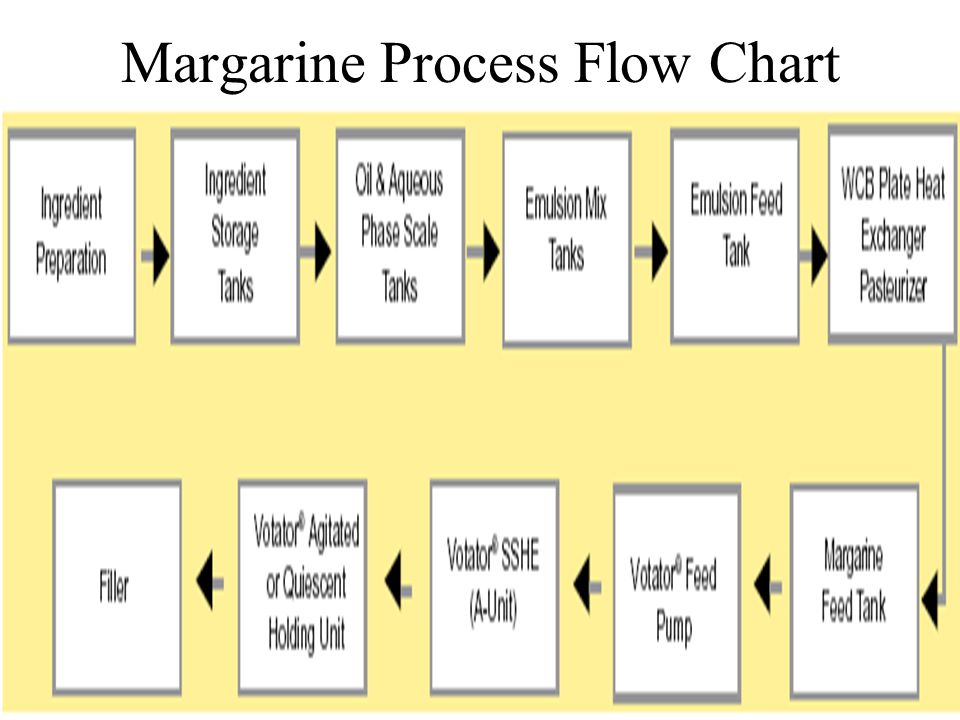

Mayonnaise-type emulsions contain a high proportion of oil often in excess of 80 yet remain OW. Flow diagram for mayonnaise production. Process Mayonnaise production can be executed in batches or In-line with a necessary production rate.

This Use Flowchart for Better Production Management uploaded by Douglas Kunde from public domain that can find it from google or other search engine and its posted under topic flow chart for mayonnaise production. The Association for Dressings and Sauces is an international association of manufacturers of dressings for salads mayonnaise mustard and specialty sauces and their suppliers. Mayonnaise is the kind of butyrous and thick sauce which is made by adding oil gradually in the egg yolk and then condiments.

Ring of a broad spectrum of products.

3 Flow Diagram For Agar Production Production Of Agar From Seaweed Png Image Transparent Png Free Download On Seekpng

Dt 12 Lesson 27 Processing Of Egg

Mayonnaise Production Line Equipment Ibc Machine

Http Www Ikausa Com Wp Content Uploads Ika Spp Maynnaise Pdf

Flow Diagram Of Whole Egg Processing Into Powder Download Scientific Diagram

How Mayonnaise Is Made Manufacture History Used Processing History Raw Materials

Comments

Post a Comment